Before you move to purchase stainless steel coils, you’ll want to learn more about their uses and transport requirements. Find out how to transport them safely using a wooden skid or pallet. Learn about their applications and dune spacing. Then, you can learn how much they cost. We’ll also discuss how to pack and protect them to prevent them from bending or becoming damaged. Continue reading for more information!

Applications

Stainless steel coils are used in a variety of industrial applications. They are extremely strong and durable, and their corrosion-resistant properties make them a perfect choice for the food and beverage industry. The term “cargo loading” refers to the process of loading cargo onto a ship at a shipping port that has been mutually agreed upon. This term has a variety of definitions and is a critical component of trade.

Stainless steel coils are used in many different industries, including the food and beverage industry, construction, and environmental protection. The automotive industry is the largest consumer of stainless steel coils, with their use increasing from ten kilograms to thirty or forty. Other industrial facilities require high-quality austenitic and duplex stainless steel coils. China’s home appliance industry is a major potential market for these materials. Additionally, they are used in various fields in the petrochemical industry and in the industrial structure.

Types

Choosing the best type of stainless steel coils to transport will depend on a number of factors. The quality and price of coils depends on the type of steel used and the size of the mills used to produce them. For example, a four-high rolling mill can only produce a 600mm width ss coil. Because of this, stainless steel coil manufacturers usually produce six tons of inventory for each buyer and store them until the next buyer comes along. However, the best price is often found at the manufacturer’s factory. There are no middlemen to deal with, so their prices are generally competitive.

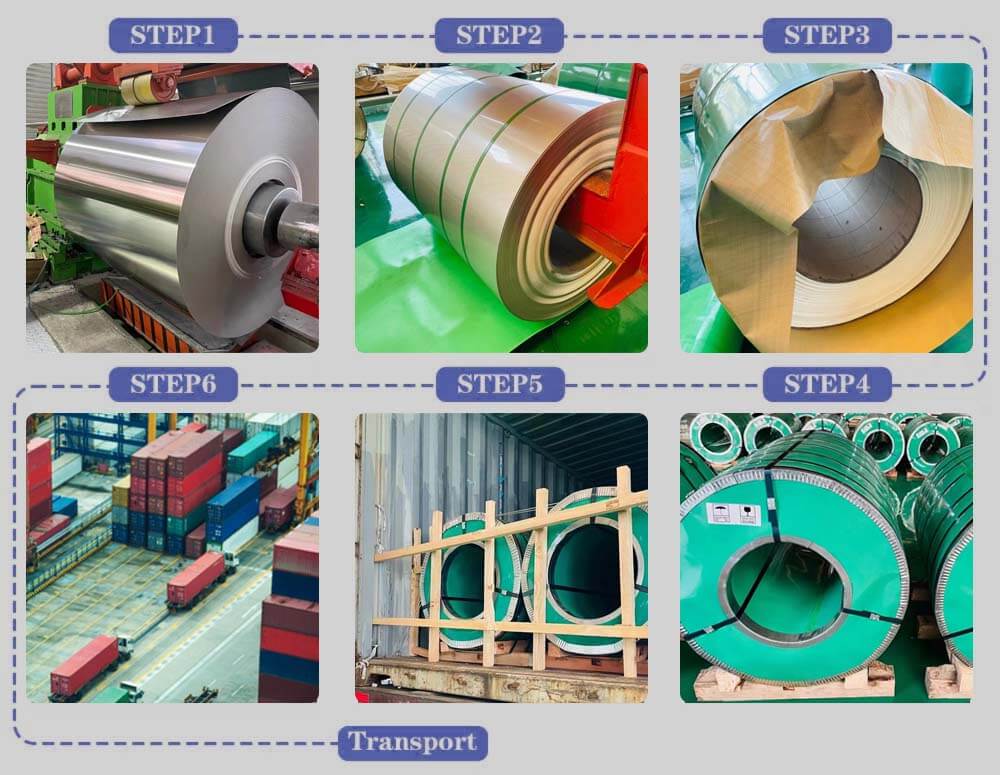

For shipping, stainless steel coils should be wrapped in plastic film that is at least 150 um thick. This outer plastic sheet covers the coil’s outer circumference and both ends. The plastic film should extend at least 30 cm into the coil’s eye on both sides. Coils should be transported in “coiltainers” or standard containers, with an additional ply of paper between the coil’s outer and inner diameters.

Dunnage

Stainless steel coils, galvanized sheet steel, and slit or tin-coated sheet metal are vulnerable to damage during transportation. Traditional means of transport have been limited due to service constraints, irregular schedules, and longer transit times. Additionally, they are more expensive and require special handling equipment. Here’s some advice. Read on to find out how to transport stainless steel coils in the most efficient manner. This way, you’ll avoid damaging your products and save money, too.

When stowing and transporting stainless steel coils, ensure the material’s edges do not protrude past the sides of the container. Make sure the coils are sized appropriately to avoid sticking out the sides of the pallet or wooden skid. The following figure shows how to properly space the coil edges. If you are unsure of what size of wooden supports to use, read the guideline carefully. Once you’ve completed the step-by-step process, your coils will arrive at their destination safe and sound.

Costs

Stainless steel coils are large, heavy, and brittle, so they can be a difficult commodity to ship. While traditional methods like rail and water transportation have their place, they can also damage the product. The following are the costs associated with transporting coiled stainless steel. Here are some tips to reduce these costs. Keep reading to learn how you can reduce these costs and ensure you get your stainless steel product to your customers in the best condition possible.

In Taiwan, prices for 300-series coil have increased by 63 percent year-on-year. Meanwhile, distributor purchasing activity has been constrained by concerns over overpriced inventories. Covid-19 infections are also negatively affecting stainless steel production and consumption. Many suppliers are reporting logistical issues due to lockdown restrictions. As a result, prices have increased by around 17 percent since the start of 2022.

Durability

Stainless steel coils are manufactured in a factory. The width of the coil depends on the size of the rolling mill. Four-high mills can produce ss coils up to 600 mm in width. A stainless steel coil manufacturer produces 6 tons of inventory to meet the demands of its customers. Then, they store this inventory until the next buyer. Stainless steel factories have high MOQs, but their prices are cheap because there is no middleman.

As long as they are produced correctly, the stainless steel coils are highly durable. To ensure their durability, you should choose coils with a standardized thickness. Stainless steel coils typically have a thickness of 0.50 to 1.0 inches. The thickness of the coil plays a major role in determining its overall durability. Cold rolled coils can be more easily dented or broken than hot rolled coils, but both types have the same tensile strength.